- Stock: In Stock

- Brand: American Smalt Company

- Model: SMALT-BLUE-FRANCE-1LB

More from this brand

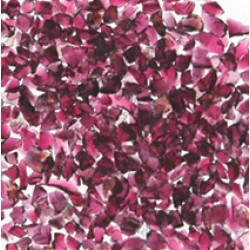

Smalts Bleu de France

Smalts Bleu de France 1 Pound Bag Medium Sized pieces (1-2.4mm), colored Signs Smalts, Smalts, Smaltz, Smalting or Osmalto is a time old tradition of making a long lasting textured Sign background by embedding aggregate smalt made fine pigmented glass or colored sands. Smaltings were most popular from 1865-1935. Originally Buildings exterior walls were coated with Smaltz from the second floor on up to extend the life of the paint job out 20-25 years. Eventually Smalts worked it's way up to the roof, and that's were we see Smalting on a mass with modern roofing tiles.

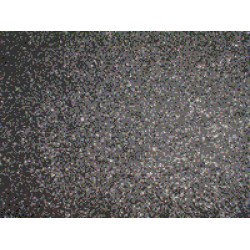

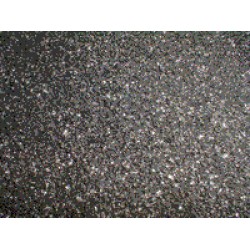

Sand Smalts how to: Sand Smaltz were created by soaking by soaking sand in a mixture of Gasoline and Pigment for 3 days to a week, then drained, followed up by throwing the stained sand against dry cardboard to absorb moisture and left to dry. Sand-Smalts make a tough surface, but the colored paint pigment still faded and don't hold up to the test of time. Sand Smaltz were nice but were eventually replaced by colored glass smaltz.

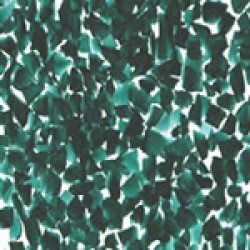

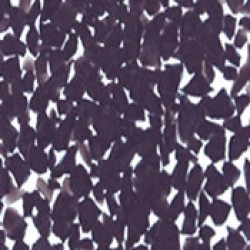

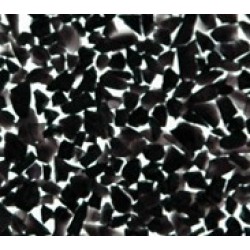

Colored Glass Smaltz are completely different. Colored Glass Smalts is made by mixing the color directly into the glass when being made, thus trapping the pigments color in glass giving Colored Glass Smaltz additional Ultra Violet ray protection from the sun. The nicest smalts are Transparent in nature, similar to precious stone like Rubies, Emeralds and Sapphires. Transparent Colored Glass Smalts allow the light rays travel through and produce beautiful sparkling smalted backgrounds that endure at a true craftsmen level.

Sign Painters and Sign Makers come from the Construction industry known as finishers and grainers, began using Smalts in their designed sign panels background and became the standard for many years still seen today in some of the nicest locations such as Disneyland, Resorts and Casinos.

Smalts-American or Imported Translucent German Smalts Colors. Smalts enhance even the simplest of signs. Make your Client's Signage unique!

Use Smalts as an accent color, for a sparkling boarder, or edge to edge background coverage with raised letters. With a smalted finish, your signs will stand out and get noticed.

Smalts, Smaltz, Smalting or Osmalto FAQ: How much smalt will I need? Typically 1 pound of smalt will cover 1 to 1 1/2 square feet of area depending on how thick you apply it.

How To Smalts Signs - A smaltz Tutorial on Osmalto

how to make a smalt background. smalted signs step by step.

- Mask off sign area you're smalting with 1/8" sandblast mask.

- Pick a paint color that matches your smalts colors best.

- Use Gilders Smalt Cream or Smiths Cream and mix 50/50 with oil based enamels such as One Shot sign painters enamel or japan oil colors.

- fill exposed areas to be smalted with 1/8" of enamel.

- Let mixed Smalt Cream and Paint stand and level for 1/2 hour. Temperatures and drying times may vary, always make a sample piece and monitor and record cure times for smalt.

- apply smalt to background by sprinkling over wet paint in light amounts, and then repeat the process as if spraying on, don't pour on all the smalt at once, but make several or more passes, allowing time to let the Smalt sink into the smalt cream paint mix. The first couple of coats of smalt will sink all the way in, but slowly after a couple of passes the smalt will build up evenly.

- Smalted areas should set and level for 15-30 minutes, then if wet areas are still visible sprinkle on more smalt on the wet surface until completely covered.

- Smalt Cream Paint mixture will left alone and not touched until cured and dry completely. Temperature and dry times vary greatly depending on your location or the time of year, wintertime can take longer to dry. Typical Smalt cure times are 24-48 hours, some taking 1 week to cure. Make a tester/sample panel to test dry time.

- Once your sure the smalt is dry you may Lift the Smalted panel and dump off excess and light pat the backside to assist, if your smalt is dry it will hold, if wet it will fall off in big chunks which you cannot repair so make sure your smalt is fully cured dry.

- Now remove any masked areas carefully. Afterwards you may then lift the sign and pat lightly and then clean up. Smalted signs tend to lose little amounts of smalt off the surface even during installations. avoid cuts from running your hands over the smalted surface, it's sharp.

Smalted Background Cliche Noe sign painter demonstration in layered m.d.o. wood gilded Gold & Silver Leaf, Air brushed, Pinstriped and Hand Lettered by sign artist Ron Percell. Advanced techniques are available through advanced workshops, and at Gilders and Letterhead Gatherings

how to make a smalt background. smalted signs step by step Video

This video is on making the whole sign shown, but in the middle of the video it show how Ron Percell did a quick Smaltzing

Related words: colored smalts, Smalts, Smaltz, Smalting, Osmalto, smalt sign smalts, smalted signs, smalting signs, smaltz signs, smalted background, smaltzs background